Table of Contents

Introduction

Once, 3D printing was limited to building test models or prototyping, but it has now become a key driver of change across various sectors. As we step into 2025 and look toward the future, 3D printing not only helps in developing objects but also reshapes designing, producing, and living. Additive Manufacturing technology now goes from printing aircraft parts to growing tissues, printing parts for cars as required, and 3D-printed buildings. Technologies such as artificial intelligence (AI), IoT, robotics, and nanotech converge with 3D printing; the field is now entering a new phase, making manufacturing hyper-personalized, sustainable, and easily accessible. Let’s explore more about the new trends, applications in the industry and groundbreaking advances that can be expected in 2025 and beyond.

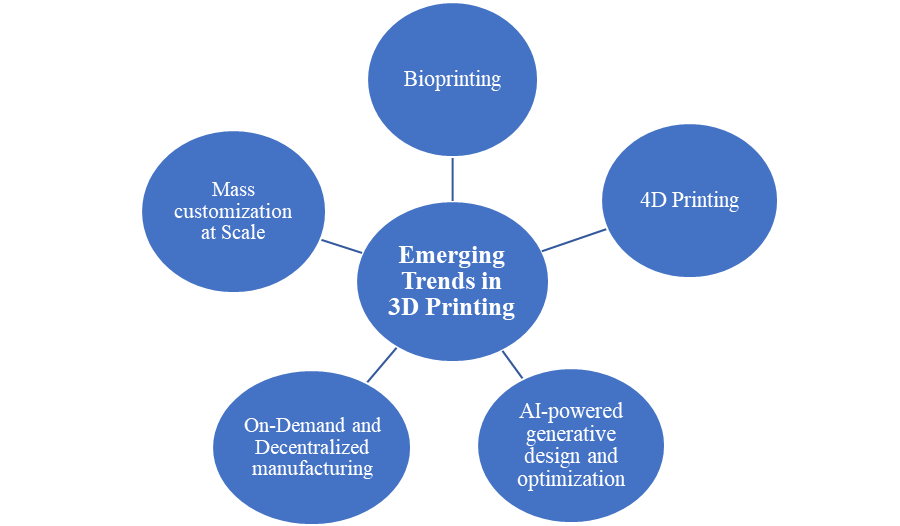

Emerging Trends in 3D Printing – 2025 and Beyond

- Bioprinting – Moving beyond tissues to functional organs: Bioprinting, which used to be a fantastic idea, is now moving closer to application in the real world. Even though printers have created skin, bones, and simple tissues, the next few years will concentrate on developing intricate structures such as vascular networks and functional organs. In 2025, bio-inks, lab-grown cell printing, and organ scaffolds will be important sources of funding. Even though regulatory and ethical issues must be resolved, bio-printed organs have the potential to minimize waiting periods for organ transplants, by avoiding rejection concerns because of personalized-specific tissues. Therefore, the convergence of 3D printing along with stem cell research, and regenerative medicine makes it an emerging frontier in the healthcare sector.

- 4D Printing – Smart materials that respond to the environment: While 3D printing helps in developing static products, 4D printing includes materials that adjust their shape after being exposed to temperature, moisture, light, or pH. The development is being noticed in the fields of fashion, aviation, and healthcare. As a result, 4D-printed stents expand inside arteries which could revolutionize the design of products. The commercial rollout of 4D-printed products is expected to rise after 2025 due to the accessibility of smart polymers and hydrogels.

- AI-powered generative design and optimization: Using generative design, AI aids in transforming design thinking depending on various input constraints such as performance, weight, type of material, and cost. This brought improvements to 3D printing that prioritized producing objects with complex designs. AI can optimize designs concerning speed, and sustainability by focusing on eliminating waste from materials. Looking ahead, AI-integrated 3D printing software will play a crucial role by offering feedback in real-time and automating corrections during the process of printing.

- On-demand and Decentralized manufacturing: The conventional method of making products in huge factories is highly disrupted by on-demand 3D printing in local areas. It is predicted that by 2025 and beyond, manufacturers will divide their operations by setting up distributed print centers. This shift helps in quick delivery, and customization in real-time and minimizes emissions from transports. For example – Amazon and other big retailers are exploring on-demand 3D printing models for consumer products thereby offering hyper-personalized goods printed locally. This significantly results in minimizing carbon footprints and storage costs.

- Mass customization at scale: In the future, additive manufacturing will become mainstream. 3D printing allows customers to modify the features of products including color, type of material, shape and size of a product without altering the production line. It plays a pivotal role in eyewear, footwear, consumer electronics and prosthetics. Consumers might expect personalized products by 2025 as a regulation instead of an exception due to scalable 3D printing platforms integrated with cloud-driven design tools and e-commerce.

Industry-Specific Transformation Using 3D Printing

- The Aerospace and Defense industry

The aerospace and defense industry has significantly integrated 3D printing because of its requirement for durable, intricate and lightweight components. Companies such as NASA, Boeing, and Airbus utilize 3D printing to minimize part weight by approximately 60% thereby reducing operational costs and consumption of fuel. Manufacturing complex geometries that were inexpensive can be developed at low cost after the advent of 3D printing. The ability to manufacture satellite parts, drones, and tools on-demand in remote regions will help redefine the agility and improve resilience in this industry.

- Automotive Industry

Automotive manufacturers are shifting to 3D printing for custom tooling, end-use parts and rapid prototyping. Companies such as Ford, Tesla, and BMW use additive manufacturing that helps in adopting new models and minimizing development cycles in the market. In addition, 3D printing allows lightweight design for electric vehicles thus improving the efficiency of energy and overall range. Furthermore, car buyers can personalize, accessories, interior parts or components and trims due to the increase in consumer personalization. By 2025, it is expected to establish local print centers where accessories and spare components are printed on demand thereby minimizing the costs of inventory and promoting the practices of the circular economy.

- Healthcare industry

The healthcare industry is primarily revolutionizing due to the advent of 3D printing. Nowadays, it is possible to offer personalized care through devices such as dental implants, prosthetics, hearing aids and surgical models. However, custom prosthetic limbs help in catering to the anatomy of individuals which is accessible and affordable even in the developing regions. Surgeons leverage 3D-printed organ models to plan intricate surgeries with high precision. In addition, crowns, aligners, dentistry and bridges are being printed thus minimizing waiting time. The advent of 3D printing for drugs and bioprinting of tissues and cartilage will strengthen patient care by 2025 and allow personalized drug dosages and regenerative treatments.

- Fashion and Consumer Goods

3D printing is redefining the fashion and consumer goods industry by manufacturing made-to-order, experimental and sustainable designs. Designers such as Iris van Herpen demonstrate 3D-printed fashions, while Adidas uses 3D-printed midsoles that cater to the user’s biomechanics. Jewelry designers make complicated, and lightweight pieces using new technology that would be challenging with the conventional methods. In terms of consumer goods, 3D printing promotes highly-personalized products thereby supporting sustainable consumption. Since consumers are more interested in uniqueness and environment-friendly products, 3D printing helps brands respond to meeting the demands.

- The construction and Real Estate industries

3D printing technology is playing a crucial role in how construction has shifted, as some printers can now construct walls, bridges and entire houses. Companies including ICON and Apis Cor are leading the change by making affordable housing in a short period. This technology helps in minimizing the costs of labor, reduce waste from materials, and accelerate timelines. In 2025, cities facing difficulty due to the scarcity of housing in natural disasters will likely use modular offices, printed homes and emergency shelters. This approach also corresponds with initiatives of smart cities thereby incorporating IoT infrastructure within printed structures

Market Outlook and Investment Trends

3D printing on a global scale is on the verge of strong growth and significant transformation. Research from Statista indicates that the market is valued at $22.6 billion in 2023 and will reach $57.1 billion by 2028. The rapid growth demonstrates the increased use of 3D printing in several industries and developing confidence among investors that leads to fostering innovation and commercialization at scale. Metal 3D printing is one of the most exciting areas that require high investment. The industrial giants and venture capitalists are paying attention to it because of its ability to build complex, and durable parts for defense, aerospace and automotive sectors. Startups and big companies are focusing on refining techniques such as Binder Jetting and DMLS to reduce costs, keep expenses down, and increase production time with greater precision. Another rapidly growing field relates to bio-inks and bioprinting since these areas are gaining interest in the printing of organs and tissues. As regenerative medicine is studied further, bioprinting businesses are making innovative bio-inks derived from living cells to develop small organs, skin grafts, and cartilage. The niche helps in attracting biotech investors, hospitals, and research institutes worldwide. 3D printing is supporting innovation. New software helps in designing, boosting efficiency and accuracy in the printing industry. The companies that offer design simulation, correct errors in real-time, and optimize files are important in the 3D printing sector and are getting major financial support. Funding is being offered by venture capital firms to innovative companies that focus on redefining additive manufacturing. Carbon3D with its ultra-fast Digital Light Synthesis technology, Formlabs, a company that offers inexpensive high-end printers, and Desktop Metal uses office-friendly metal printers tends to invest heavily and expand worldwide.

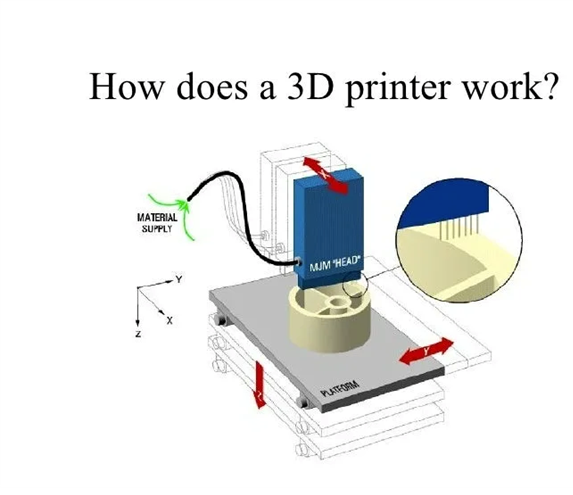

How 3D Printers Works?

3D printers create objects by additive manufacturing, starting with a flat layer and adding more layers to develop a physical item from a digital design. Usually, a 3D model is built using Computer-Aided Design (CAD) software or by scanning from the existing objects. This model is then further divided into various horizontal layers using special slicing software.

As soon as the design is prepared, the printer begins its work. Layers are built by the printer’s nozzle or by integrating materials like PLA, ABS, resin, metal powder, and biological cells. Therefore, each layer added to the sculpture stays bonded, eventually developing a complete object.

Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS) are several technologies of 3D printing which is highly suitable for particular materials and applications. The beauty of 3D Printing depends on the ability to produce intricate geometrics thus reducing waste from materials. It also enables rapid prototyping from the automated and compact machines.

Evolution of Material beyond Plastic and Resin

3D printing materials are diversifying rapidly. Metals, glass, food-based materials, concrete and ceramics and even living cells are being printed along with conventional thermoplastics. Various sustainable alternatives such as biodegradable filaments, plant-based polymers and recycled plastics are also gaining popularity. Additionally, metal printing using aluminum or titanium in various industries such as aerospace, and construction ensures structural strength with reduced weight. The materials produced will be robust, lighter and sustainable in the future.

Challenges in Holding 3D Printing

- High operational costs and initial investment – Industrial-grade machines tend to remain inexpensive despite a decrease in the prices of consumer-grade 3D printers. Scaling up 3D printing is not easy because it requires high costs, maintenance, and hiring professionals. Additive manufacturing usually requires dedicated efforts after building, which might be time-consuming and expensive. All these factors make it challenging for small businesses to expand their use of technology without external funding.

- Lack of materials and material properties – Even though the range of materials for 3D printing is growing rapidly but still finds it difficult to match the performance of conventional manufacturing materials. Some printable materials have limited strength, are resilient against heat, and work in high-stress settings. Metal printing still requires a lot of time, is expensive and is technically challenging. Furthermore, multi-material printing along with mechanical components is under development thus hindering innovation in sectors such as smart devices and robotics.

- Performance and issues of scalability – Various individuals value 3D printing concerning speed in prototyping but still lag behind conventional methods of manufacturing such as injection molding. Printing extensive items might require a considerable amount of time-based on the size and complexity. Moreover, if the printer stops working, needs to be calibrated, or is slow during post-processing will significantly result in affecting its practicality for continuous operations at a large scale.

- The processes of Quality Control and Standardization – It is difficult to maintain consistent quality across several operators, machines, and materials used in additive manufacturing. Even minor alterations in temperature, settings of software and humidity might result in inconsistencies in final products. The lack of certification protocols increases challenges in the regulated sectors such as medical devices, aerospace and automotive where the safety and reliability of products cannot be negotiated.

- Training workforce and skill gaps – 3D printers require specialized knowledge to operate and maintain effectively and efficiently. However, various enterprises face difficulty finding experts trained in machine operations, 3D design and material science. The skill gap directly leads to reduced innovation and implementation, particularly in regions where additive manufacturing, training programs and education are still limited. Therefore, bridging this gap helps in developing a capable workforce to revolutionize 3D printing,

- Environmental Impact and waste – 3D printing assists in saving the environment, despite being marketed as a sustainable alternative. It is challenging to recycle plastics and resins since they are non-biodegradable. Furthermore, consumption of energy particularly in metal and large-scale printing is a substantial option. Even though 3D printing offers environmental advantages but remains partially unrealized without having an effective closed-loop material system.

- Legal and intellectual property concerns – 3D printing is becoming more accessible, and thus results in IP theft and counterfeit production. However, digital blueprints for products can be shared, printed, or copied without seeking prior approval. This situation poses serious challenges for content creators, manufacturers, and designers. As the industry develops further, there will be a requirement for comprehensive cybersecurity protocols and digital rights management (DRM).

Conclusion

From 2025 and beyond, 3D printing has been embraced and is revolutionizing various industries and the lives of individuals and economies. Bioprinting, smart materials, and AI-driven design make it possible to print aerospace parts, organs, homes and consumer goods. The shift towards the practices of sustainability, localized manufacturing signals and mass customization help in developing a future that ensures rapid production and driving sustainability.

On the other hand, realizing the potential of 3D printing and also includes various challenges, including expensive equipment, shortage of materials, problems with quality control, and regulatory challenges. Even so, constant efforts, research, and collaboration across different sectors help in eliminating these challenges and bridging these gaps. With the continued progress of startups and global corporations, 3D printing plays a key role in advanced manufacturing. The field of 3D printing will completely shape the coming decade. People who respond early will stay updated and guide the progress in the future.